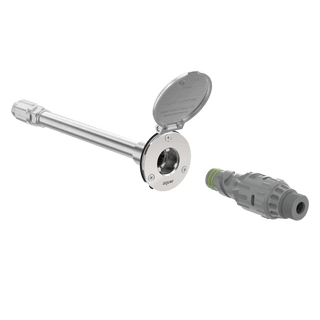

All the Aquor products are well designed, thoughtfully engineered and they just work beautifully!!! I have two of the V2+ water hydrants, and two of the new retractable hose reels and they not only work beautifully, they also look stunning and modern. So having those products made me interested in trying the new utility spray nozzle. It has the same quality and durability. It’s easy to use and comfortable to hold and feels good in my hand. It has 2 controls to change the flow of water and the water pattern and there’s a metal loop to lock the trigger in place to prevent hand fatigue.